Crafting a Full-Grain Leather Wallet

Every full-grain leather wallet begins as something raw and honest. It isn’t born on a factory line but drawn from nature itself, a hide marked with grain, texture, and time. Turning that material into something enduring is a patient craft. It calls for steady hands, good tools, and respect for the leather’s story.

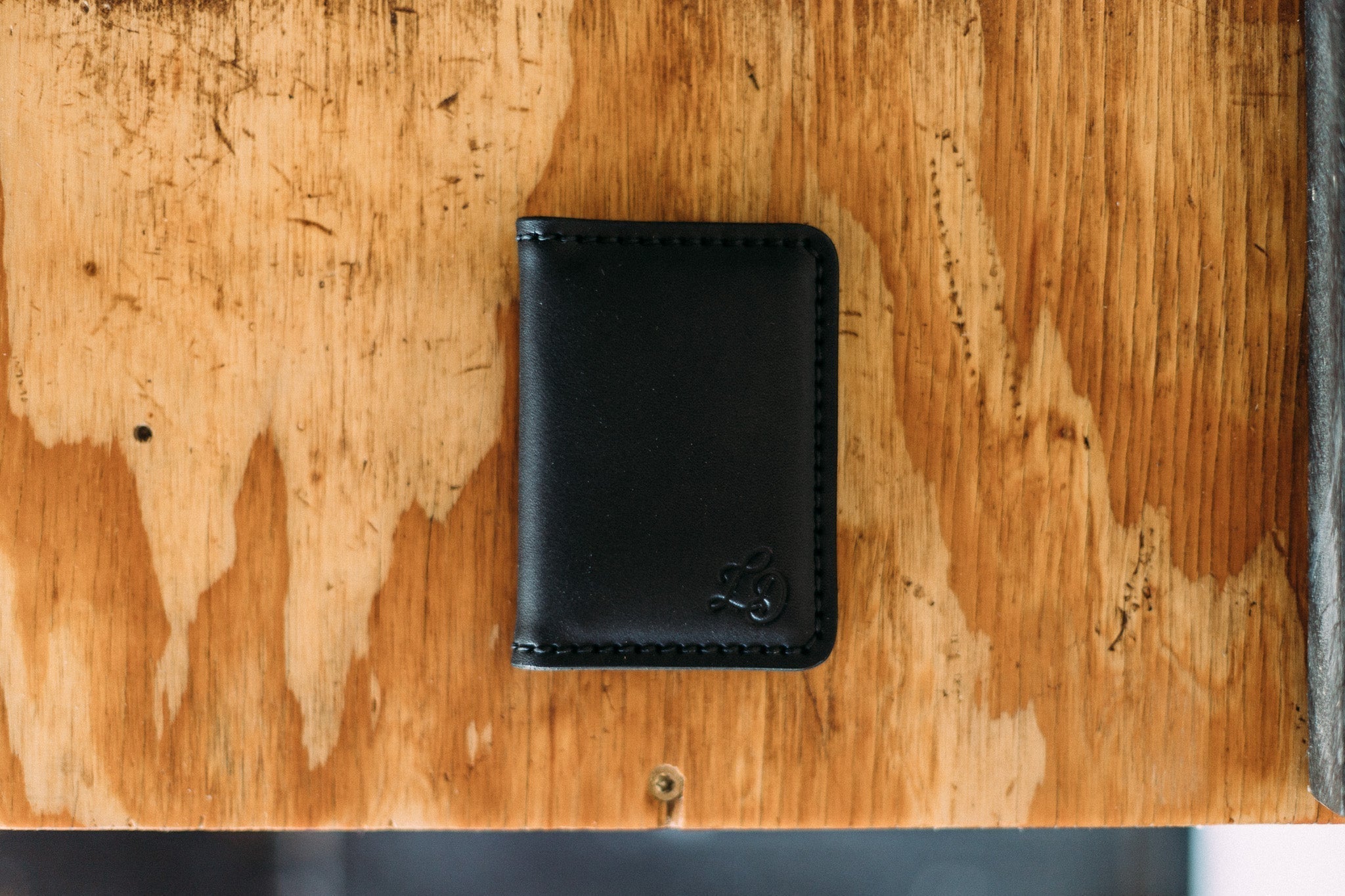

Most people never see what goes into leather wallet making. They see the finished product, clean edges, neat folds, and polished shine, without realizing that every mark, stitch, and cut carries intention. In the hands of a craftsman, those details are what transform a piece of hide into a trusted companion that lasts decades.

This is how crafting leather wallets happens at Lost Dutchman Leather: a conversation between tradition and precision, guided by skill and patience.

Step One: Selecting the Leather

Everything starts with the hide. For wallets built to last, only full-grain leather will do. It’s the top layer of the hide, dense, breathable, and filled with natural fibers. Unlike corrected leather that’s sanded smooth to hide blemishes, full-grain keeps its marks: small scars, folds, and subtle variations that tell the story of the animal’s life.

These details aren’t flaws. They’re authenticity is written into the material itself. When shaped into a wallet, those natural patterns influence the patina that forms over years of use, making every piece truly one of a kind.

The same philosophy drives every Lost Dutchman piece, from the Card Holder Collection to the Dutchman Bifold. Each begins with full-grain hides chosen for character, not perfection.

Step Two: Precision Cutting

Once the leather is ready, the real shaping begins. Precision cutting defines how the wallet will function for decades. Each panel must line up perfectly. Even a fraction of a millimeter off can throw the entire build out of balance.

Cutting leather isn’t guesswork; it’s discipline. The craftsman studies the grain and direction of the fibers the same way a woodworker studies grain before cutting a plank. Sharp knives, steel rulers, and steady hands take the place of machines.

For designs like the Franklin Wallet, where no stitching exists, precision is everything. The entire wallet depends on clean folds and exact edges. One wrong cut and the piece can’t be salvaged.

This stage of leather wallet making is quiet, deliberate, and almost meditative, an artisan matching the shape of the design to the strength of the hide.

Step Three: The Stitching Process

If the leather provides the body, stitching gives the wallet its backbone. The best wallets are hand-stitched using the saddle stitch method, a time-tested technique older than most modern machines.

With two needles moving through the same hole from opposite sides, every stitch locks into itself. The seam won’t unravel even if one thread snaps. Machine stitching, while faster, can never promise the same resilience.

It’s a rhythm you can almost hear: the pull of thread, the creak of the leather, the soft snap as each stitch tightens. In workshops like Lost Dutchman’s, artisans often work with a stitching pony, a small vise that holds the wallet upright, letting both hands move freely.

The Vertical Dutchman and the Dutchman Bifold are both sewn this way, built for decades of use, not just a season or two.

Step Four: The Art of Burnishing

Edges are where good craftsmanship shows. In mass-produced pieces, edges are often left raw, rough to the touch and prone to fraying. In true crafting leather wallets, that’s never acceptable.

Burnishing smooths and seals those edges until they’re strong enough to resist moisture and friction. The process is simple, but the skill comes in the finish:

-

Sand the raw edge until it’s even.

-

Apply natural gum or wax compound.

-

Rub vigorously with wood, bone, or canvas to compress the fibers.

Done right, the edge darkens and shines, becoming as smooth as glass. It’s one of those details you might not notice at first, but it’s the difference between something that feels handmade and something that feels timeless.

Even smaller items, the AirTag Keyring or Lanyard – Large, receive the same treatment. Consistency in finishing proves care at every scale.

Step Five: Personalization and Patina

Leather changes because it’s alive. It breathes, stretches, and responds to touch. Over time, a wallet begins to take on the character of its owner, the pattern of the pocket it rests in, the oil from the skin that darkens its tone, the marks of use that tell quiet stories.

This transformation is called patina, and it’s one of the great rewards of owning full-grain leather. A brand-new wallet looks good; one that’s been carried for years looks right.

-

The surface deepens in color where it’s handled most.

-

Edges round off and smooth with friction.

-

Folds soften and shape themselves to your carry style.

A wallet like the Mini Franklin develops this patina faster than larger designs because of its size and the frequency of handling. Over time, the slim piece becomes something unmistakably personal.

The same is true for items like the Catch-All Tray. It begins clean and structured, then slowly earns its own marks, a physical record of keys, coins, and years of routine.

Step Six: Finishing and Inspection

Before any wallet leaves the workshop, it passes through inspection. The craftsman checks every seam, flexes each fold, and verifies that card slots slide smoothly but hold securely.

Leather is conditioned lightly with natural oils to keep it supple. A soft cloth buffs the surface, bringing out the first glimmer of sheen that will evolve into patina later.

This is also the final test of alignment and structure, no uneven cuts, no weak threads. Only when it meets the brand’s exacting standard does the wallet earn the Lost Dutchman name. The same scrutiny applies to belts and other accessories; each piece must feel solid, not delicate.

Beyond Technique: A Philosophy of Craft

True crafting leather wallets isn’t just a checklist of steps. It’s a belief system grounded in respect for the material, the time, and the person who will eventually carry it.

Three principles guide the process:

-

Respect for the hide. Every piece is used thoughtfully; waste is minimized.

-

Pride in the craft. Hand-stitching may be slower, but it creates a connection between maker and material.

-

Commitment to longevity. Products are built to be repaired, not replaced.

That philosophy flows through everything made at Lost Dutchman Leather. Even simple pieces like Limited Leather Coasters reflect it: the same materials, the same hands, the same devotion to durability.

American Heritage and the Human Hand

Leather craft runs deep in American tradition. Saddles, belts, and holsters were built to withstand years of hard use. The same mindset continues today in modern workshops that blend traditional methods with modern precision.

Supporting handmade wallets means supporting that heritage. It keeps alive the skills machines can’t imitate: the rhythm of hand-cutting, the feel of tension on a thread, the eye for when an edge looks “right.”

In the Lost Dutchman shop, every wallet stands as part of that lineage. Full-grain hides, natural dyes, burnished edges, it’s not nostalgia; it’s respect for what has always worked.

The Life of a Well-Used Wallet

Picture a wallet carried for twenty years. The leather has darkened into deep mahogany. The stitching, still tight, has worn smooth under the fingertips. The edges gleam like river stones.

It’s more than an accessory; it’s a small archive of its owner’s life. Every crease means something: a favorite cafe, a move across states, the rhythm of daily carry.

That’s the difference between something made by hand and something made by machine. One expires; the other evolves.

Final Reflection

Leather wallet making is both methodical and soulful. From selecting hides to burnishing edges, each phase combines precision with patience. The process rewards experience; every decision, from grain direction to stitch length, influences how the wallet feels years down the line.

At Lost Dutchman Leather, that process defines everything we do. Wallets like the Franklin, Mini Franklin, and Dutchman are built the same way: cut by hand, stitched for strength, and finished with respect.

Explore our Wallet Collection or contact us to learn more about the materials and methods behind each piece. Because a wallet shouldn’t just hold what you carry, it should hold the story of how it was made.